Slotted Liner Screen, Sand Control Oil Pipes

The slotted pipes or liners using in oil exploration can prevent 99% sand, decrease 80% of oil well heavy repair and increase the oil well's strength, integrality and stability of keeping off sand. Meanwhile, the laser incision can make very small cuts with smooth surface and high precision. Although its structure is simple, it is very effective. It has small cuts of 0.10-0.5 mm in the tube wall.

The slotted pipe works by allowing certain particle size coming through the surface with crude oil while keeping the bigger size sand staying outside, and thereby the anti-sand purpose is achieved.

Line slot pattern, staggered slot pattern, multiple staggered slot pattern.

Slotted liner screen has several unique advantages when compared with using of perforated pipes.

Stainless steel slotted liner screen with staggered slot pattern for oil and gas well sand control

- Material: Stainless Steel 304 / 316L or API J55 / N80 / Q125 casing

- Slot Pattern: Staggered slots (multi-row offset pattern)

- Slot Width: 0.10 mm – 0.50 mm (laser-cut high precision)

- Slot Length: 20–100 mm

- Open Area: 6% – 12% depending on slot density

- Outer Diameter: 2-3/8" to 13-3/8" (60 mm – 340 mm)

- Wall Thickness: 5–12 mm

- Pipe Length: R1, R2, R3 (6 m – 12 m standard)

- Advantages: Prevents up to 99% sand, reduces 80% well repair, smooth laser-cut edges

Straight-line slotted sand control oil pipe with precision long slots for downhole filtration

- Material: Carbon Steel / Stainless Steel / API Casing

- Slot Pattern: Straight line slots (continuous axial layout)

- Slot Width: 0.15 mm – 0.40 mm

- Slot Length: 40–120 mm

- Slot Orientation: Parallel to pipe axis

- Outer Diameter: 73 mm – 339.7 mm

- Wall Thickness: 6–10 mm

- Pipe Length: 6 m / 9 m / 12 m

- Performance: High flow capacity, effective sand retention, suitable for high-permeability formations

Multiple staggered slotted liner with uniform long slots for oil and gas well sand control applications

- Product Type: Slotted Liner for Sand Control

- Material: SS304, SS316L, Duplex, API N80 / L80 / P110

- Slot Pattern: Multiple staggered rows (3–6 staggered lines)

- Slot Width: 0.20–0.50 mm, laser-cut

- Slot Length: 50–150 mm

- Open Area: 8% – 15%

- Outer Diameter: 2-7/8" to 10-3/4" (73–273 mm)

- Wall Thickness: 5.5–12.7 mm

- Pipe Length: 6–12 meters, API standard

- Application: Horizontal wells, high sand production wells, deep formations

Features

The slotted liner is a robust and cost-effective solution for long completions or low productivity wells.

We offer straight and key stone slot in a wide range of slotting patters to satisfy the required open area.

High rigidity resisting scrape and abrasion, high intensity, anti-corrosion and even distribution.

Main technical data:

Material: stainless steel, carbon steel

Categories of pipes: petroleum casing pipe, oil pipe

Length of pipe (single): ≤15m

Outside diameter of pipe: 50 to 200mm

Wall thickness ≤16mm

Width of slot: (0.10-0.40)mm±0.03mm

Number of slots: according to order

Distribution types of slots: parallel, crisscross, spiral

Distance of slots: according to order

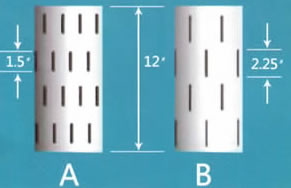

Slotted pipe screen, single line slot illustration