Mining Vibrating Screen Mesh – Essential Sieving Element for Vibrating Screen Performance

Zhongpu Co. supplies Mining Vibrating Screen Mesh made from high-tensile steel, manganese steel, and stainless steel, with customizable mesh sizes, wire diameters, and edge types. Designed for mining, quarrying, coal preparation, and mineral processing, it delivers high-strength screening performance, excellent wear resistance, accurate particle separation, and long service life under heavy vibration. This mesh reduces downtime and offers a cost-effective solution for large-scale screening operations.

Stainless Steel Mining Vibrating Screen Mesh – 0.5–12 mm Wire Diameter, 1–100 mm Aperture, 0.5–2.5 m Width

Double-Layer Stainless Steel Vibrating Screen with Hooked Edges for Load-Bearing and Precise Screening

65Mn Screen Mesh Panel Sizes for Mining Screens (0.5–2.4 m Width, 1.0–3.6 m Length),Wire Diameters (1.0–12.7 mm)

65Mn Manganese Steel Slotted Screen Mesh – 0.5–20 mm Slots, Custom Cut-to-Size Panels, Horizontal or Vertical Slot

Vibrating slotted screen mesh panels for coal washing plants typically feature slot widths from 0.2 mm to 20 mm, panel sizes up to 2500 mm × 3000 mm, thicknesses from 3 mm to 12 mm, and are made from high-wear materials such as 65Mn steel, stainless steel, or polyurethane for efficient wet screening and coal separation.

Specifications

- Mesh Aperture Size (Opening Range): 0.15 mm – 100 mm for fine to coarse screening

- Wire Diameter: 0.5 mm – 12 mm

- Screen Panel Width: 0.5 m – 2.5 m (custom widths available)

- Screen Panel Length: 1.0 m – 6.0 m (cut to size upon request)

- Material: 45# and 65Mn high-tensile steel, 30Mn and 65Mn manganese steel, SS304, SS316, and SS430 stainless steel

- Weaving / Crimping Types: Square mesh, rectangular mesh, plain weave, lock crimp, intermediate crimp, double crimp

- Edge Types: Hooked edges, flat edges, reinforced edges, welded frames

Applications

- Mining and Ore Processing

- Quarry and Aggregate Screening

- Coal Preparation and Coke Plants

- Mineral Separation and Beneficiation

- Metallurgy and Smelting Industry

- Cement, Chemical, and Recycling Plants

High-Efficiency Oil Vibrating Sieving Mesh for Global Oilfield Applications

Zhongpu vibrating sieving mesh is manufactured with high-efficiency double-layer felt screens and is widely supplied to oilfields worldwide.

- Structural Advantages: The mesh is a key wear component of vibrating equipment. A felt-coated interface bonds the metal plate and screen cloth into a single reinforced structure, ensuring stable screening performance.

- Main Features: Low cost, easy installation and replacement, long service life, and highly reliable performance make it the ideal fitting for oil vibrating sieves.

Hook Types for Oil Vibrating Sieving Screen

- Wide Industrial Applications: Oil vibrating sieving screens are used for separating small and medium-sized particles in mining, coal processing, stone crushing, ceramics, chemical production, refractory materials, and grain screening.

- Multiple Hook Options Available: Different hook styles are designed to match various screen installations. Customers can select suitable hook types based on equipment specifications and application needs.

- Hook Classification by Mesh Edge Treatment: Vibrating screen hooks are defined by the mesh edge structure. They are generally divided into five main types, each with specific configuration details and installation uses.

The first type is wire bending instead of using the plate.

The diameter of wire for screen fabrics is 6.00mm at least.

The second type is wire mesh welded plate bending.

The diameter of wire applied for vibrating screen is 4.00mm at least.

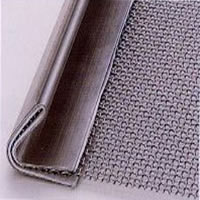

The third type is with steel flooring and then is bent into u-shaped hooks.

The diameter of wire applied for screening is between 1.0mm and 4.5mm.

The fourth type is steel hooks with rubber gasket (natural white rubber) which is type of wood flooring. It can be rivet welding to be bonded to wire mesh fabrics.

This diameter of wire for screening is mainly 1.0mm.

The fifth type is with wood flooring.

The steel plate is fixed on the vibrating screen and it is difficulty to pull it out.

Then riveted together with the screen fabrics to form a whole body.

The diameter of wire is mainly 1.0mm.