Mining Industry Screen Mesh, Ore Screening Mesh and Mine Sieve Filtration Plate

Mine screen mesh is a metal net structure components used in sieving, sifting and filtering of mine metals. Structures can be woven mesh, crimped coarse mesh, welded wedge wire or slotted metal sheets. Widely used in many industries in screening and filtering, desliming, dehydration and other operations. It has high strength, stiffness and carrying capacity, can be made into various shapes of the rigid screening filter unit.

Variety: Stainless steel welded mine screen mesh, sifting plate, sieve bend, basket, vibration screen, cylinder, arc sieve net straight wire mesh, high strength ore screen mesh, polyester mesh, etc.

Material: titanium wire, nickel wire, stainless steel wire, galvanized wire, iron wire, steel wire.

Features: Easy leakage, wear resistance, corrosion resistance. Acid and alkali resistant, high temperature resistant, strong tensile and abrasion resistance.

Use: It is widely used in mining, coal, petroleum, pharmaceutical purification, drilling fluid purification, fertilizer, grain, salt industry, environment protection, etc. Sieving and sifting liquid, powder and other materials.

Type: Mining screen mesh is an essential component in mineral processing operations, used to separate materials based on size and density. It is available in a wide variety of types and materials to suit different applications and requirements.

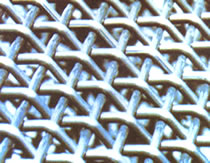

Stainless Steel Welded Mine Screen Mesh

This type of mesh is constructed by welding individual wires together, creating a strong and durable screen. It is often used for coarse screening applications, such as removing large rocks and debris from ore.

- Material: Typically made of stainless steel, such as Type 304 or Type 316.

- Weave Pattern: Often a plain weave or twill weave.

- Width: 1 meter to 3 meters

- Length: 5 meters to 10 meters

- Mesh Opening: 2 mm to 100 mm

- Ore screening: Separating valuable minerals from waste material.

- Sizing: Classifying materials based on particle size.

- Dewatering: Removing excess moisture from materials.

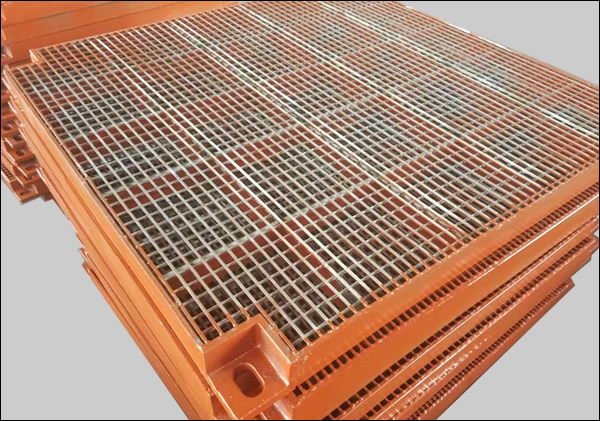

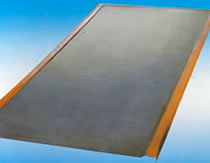

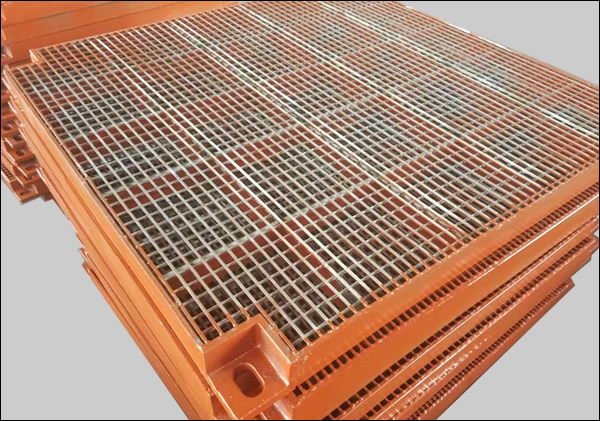

Mining Sifting Plate

sifting plates are flat screens with perforated openings of varying sizes. They are used for more precise particle separation and are often made of materials like stainless steel or rubber.

- Dimensions: Vary widely depending on the application, but typical sizes range from 1 meter to 3 meters in width and length.

- Thickness: Varies depending on the material and application, but is typically between 5 mm and 20 mm.

- Shape: Rectangular, square, or custom shapes.

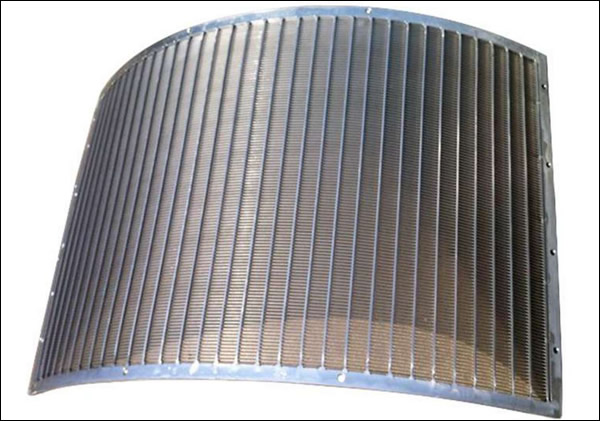

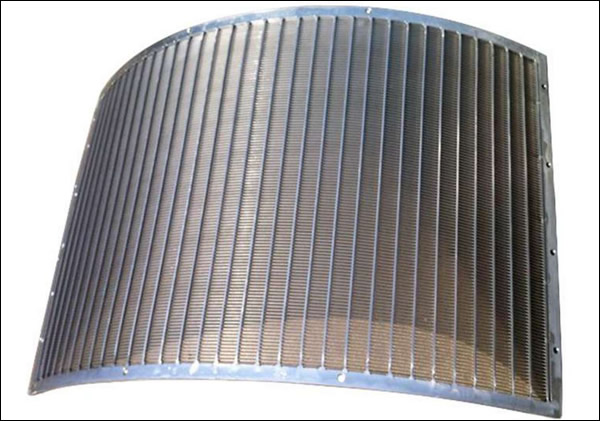

Curved Sieve Bend Screen

Curved sieve bend screens are designed with a curved shape to improve the flow of material and enhance separation efficiency. They are commonly used in wet screening applications.

Base Specifications:

- Screen Width: 12 inches (304.8 mm)

- Screen Length: 17.5 to 18 inches (444.5 to 457.2 mm)

- Curve: Approximately 1 inch (25.4 mm) in 17.5 inches (444.5 mm)

- Wire Size: 0.040 inches (1.016 mm)

- Wire Gap: 0.012 inches (0.3048 mm)

Other Specifications:

- Sieve Screen Material: 3/8-inch opening (9.525 mm)

- Screen Size: 5 feet x 5 feet (1524 mm x 1524 mm) or other sizes

- Wedge Wire Sieve Bend:

-Slot opening: 0.5 mm

-Wire width: 1 mm

-Screen size: 562 mm wide x 635 mm long

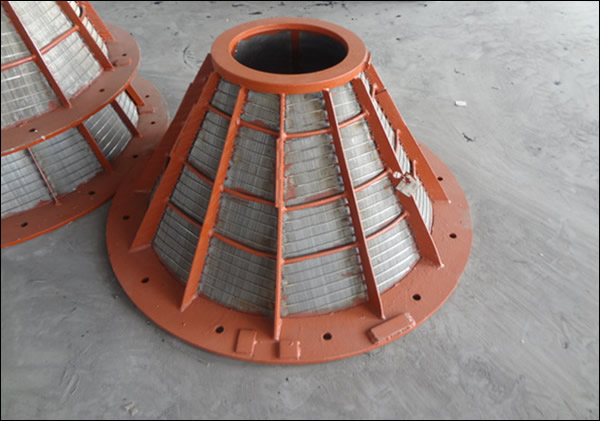

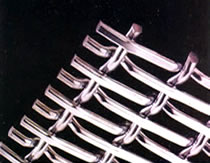

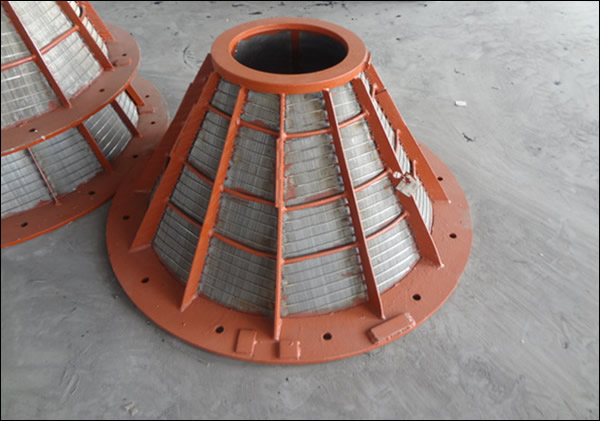

Wedge Wire Basket Strainers

Wedge wire basket strainers are made up of wedge-shaped wires that create a self-cleaning screen. They are ideal for applications where clogging is a concern, such as slurry filtration.

- Material: Typically made of stainless steel.

- Wire Diameter: Varies depending on the required filtration accuracy and strength. Common wire diameters range from 0.5 mm to 3 mm.

- Slot Opening: The distance between the wires, which determines the size of particles that can pass through. Common slot openings range from 0.1 mm to 10 mm.

- Basket Shape: Can be cylindrical, conical, or rectangular.

- Support Structure: May have a supporting structure to hold the basket in place.

- Cleaning Mechanism: Some basket strainers have self-cleaning features, such as backwashing or vibration.

Wire Shapes

- V-shaped: The most common shape, offering high open area and good filtration efficiency.

- W-shaped: Provides even higher open area and is suitable for applications with high flow rates.

- Y-shaped: Offers a combination of high open area and strength.

Common Sizes

- Small: Diameter: 100-200 mm, Length: 200-300 mm

- Medium: Diameter: 200-300 mm, Length: 300-500 mm

- Large: Diameter: 300-500 mm, Length: 500-1000 mm

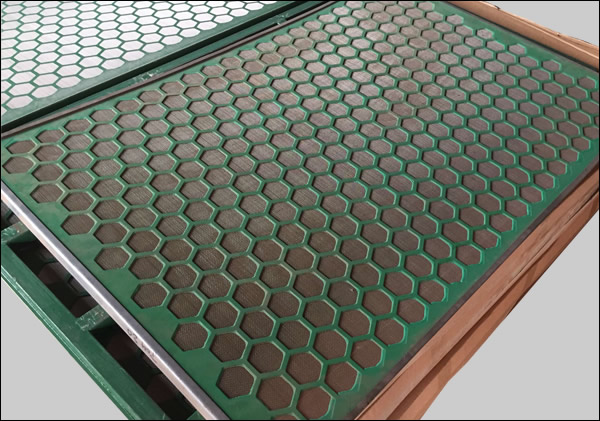

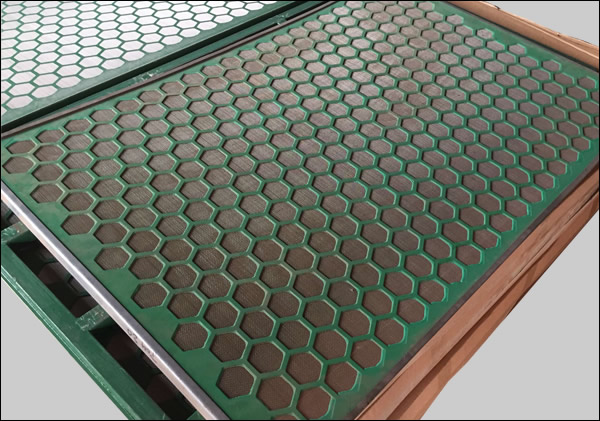

Vibration Mesh Screen

Vibration mesh screens use mechanical vibrations to separate materials based on size and density. They are widely used in mining and mineral processing operations.vibration mesh screens and shale shaker screens are valuable tools in the mining industry. While vibration mesh screens have a broader range of applications, shale shaker screens are specifically designed for the efficient processing of shale. The choice between the two depends on the specific needs of the mining operation.

Shale shaker screens are essential equipment in the oil and gas industry for separating shale from drilling fluid and other contaminants.

Size

- Width: 2-6 meters

- Length: 3-10 meters

- Deck Slope: 10-15 degrees

Material

- Frame: Carbon steel or manganese steel

- Screen Panels: Stainless steel, rubber, or polyurethane

Wire Diameter

Mesh Opening

Vibration Mechanism

- Eccentric Shafters: Commonly used

- Electromagnetic Vibrators: Provide precise control

Capacity

- Throughput: Can process hundreds of tons per hour

- Feed Size: Typically handles material up to 1 meter (3 feet) in size

Operating Conditions

- Temperature: -20°C to 60°C (-4°F to 140°F)

- Moisture Content: Up to 100%

- Abrasion: Designed to withstand abrasive materials

Types

- Single-deck: One screening surface

- Double-deck: Two screening surfaces

- Triple-deck: Three screening surfaces

Wedge Wire Screen Cylinders

Wedge wire screen cylinders are cylindrical screens with wedge-shaped wires that provide high efficiency and low blinding. They are often used in slurry filtration and dewatering applications.

Wedge wire screen cylinders are a type of filtration equipment used to separate solids from liquids. They are characterized by their wedge-shaped wire mesh, which provides high efficiency and resistance to clogging.

- Material: Typically made of stainless steel, but other materials such as bronze, brass, or Hastelloy can be used.

- Wire Diameter: Ranges from 0.5 mm to 3 mm, depending on the required filtration accuracy and strength.

- Slot Opening: The distance between the wires, typically ranging from 0.1 mm to 10 mm.

- Cylinder Diameter: Common diameters include 100 mm, 150 mm, 200 mm, 300 mm, and 500 mm.

- Cylinder Length: Common lengths include 500 mm, 750 mm, 1000 mm, and 1500 mm.

- Mesh Count: 4-10 mesh: Used for coarse screening of large particles, such as rocks and gravel.14-48 mesh: Used for medium-sized particles, such as sand and coal, 60-200 mesh: Used for fine particle filtration, such as in water treatment and chemical processing. 230-400 mesh: Used for ultra-fine filtration, such as in pharmaceutical and electronics manufacturing.

- Open Area: The percentage of the screen surface that is open, typically ranging from 10% to 50%.

- Cleaning Mechanism: Cylinders have self-cleaning features, such as backwashing or vibration.

- End Caps: End caps are used to secure the wire mesh within the cylinder and have different designs.

Corrosion Resistance:

- Stainless Steel: Excellent corrosion resistance in most environments.

- Hastelloy: Highly resistant to acids, alkalis, and other corrosive substances.

- Monel: Offers good corrosion resistance in marine environments.

Temperature Resistance:

- Typical Range: -40°C to 200°C (-40°F to 392°F)

- High-Temperature Alloys: For temperatures above 200°C, materials like Inconel or Nimonic can be used.

Pressure Resistance:

- Typical Range: 0.5 bar to 10 bar (7.25 psi to 145 psi)

- Higher Pressures: For higher pressure applications, reinforced cylinders or specialized materials can be used.

Flow Rate:

- Varies Widely: Flow rate depends on the cylinder's dimensions, mesh size, and the fluid properties.

- Typical Range: 100 liters/hour to 10,000 liters/hour or higher.

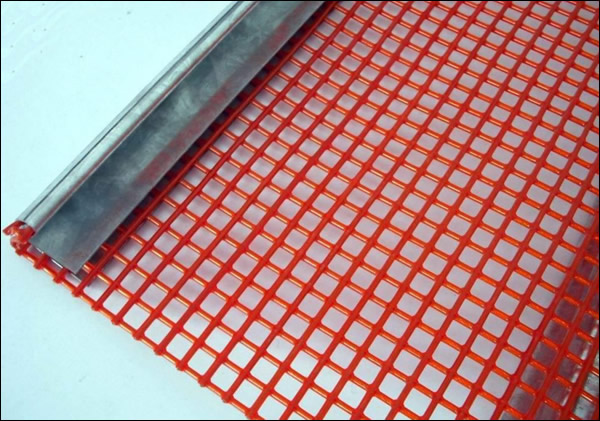

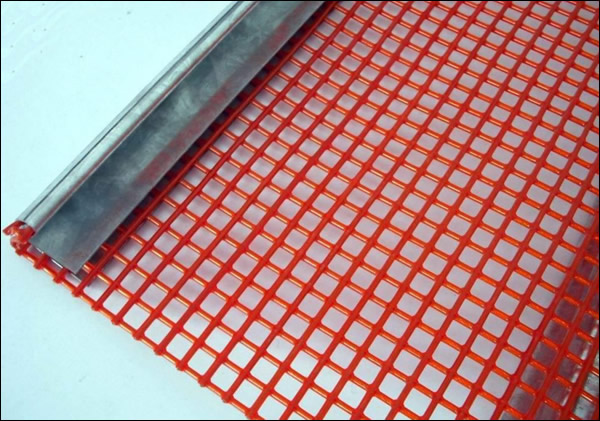

Polyester Mesh for Mining

Polyester mesh is a versatile material used in mining operations for various applications, including filtration, screening, and reinforcement.

Material

- Polyester Type: Polyester mesh can be made from various types of polyester fibers, such as polyethylene terephthalate (PET) or polybutylene terephthalate (PBT).

- Yarn Count: The number of yarns per unit length, which affects the mesh opening size and strength.

- Denier: The weight of a specific length of yarn, which determines the thickness and strength of the mesh.

- Weave Pattern: Can be plain weave, twill weave, or other patterns, affecting the mesh's strength and properties.

- Color: Typically available in black or white, but other colors can be customized.

Mesh Count:

- Coarse: 4-10 mesh

- Medium: 14-48 mesh

- Fine: 60-200 mesh

- Ultra-fine: 230-400 mesh

Mesh Opening:

- Coarse: 0.5 - 2.0 mm

- Medium: 0.25 - 0.5 mm

- Fine: 0.05 - 0.25 mm

- Ultra-fine: Less than 0.05 mm

Open Area:

- Typical Range: 10% - 60%

- Higher Open Area: For applications requiring high flow rates and low pressure drop.

- Lower Open Area: For applications requiring finer filtration.

Wire Diameter:

- Typical Range: 0.05 - 0.25 mm

- Thicker Wires: For greater strength and durability.

- Thinner Wires: For finer mesh openings and increased filtration efficiency.

Tensile Strength:

- Typical Range: 50-200 MPa (7,250-29,000 psi)

- High-Strength Grades: Can exceed 300 MPa (43,500 psi)

Elongation:

- Typical Range: 5-20%

- High-Elongation Grades: Can exceed 30%

Abrasion Resistance:

- Excellent: Polyester is generally highly resistant to abrasion.

- Specialized Grades: Some polyester meshes are specifically designed for abrasion-resistant applications.

Chemical Resistance:

- Good: Polyester is resistant to most acids, alkalis, and solvents.

Limitations: May be susceptible to strong oxidizing agents or concentrated acids.

Temperature Resistance:

- Typical Range: -40°C to 150°C (-40°F to 302°F)

- High-Temperature Grades: Available for applications up to 250°C (482°F)

Dimensions

- Width: Available in various widths, typically ranging from 1 meter to 3 meters.

- Length: Available in various lengths, typically ranging from 50 meters to 100 meters.

- Roll Weight: The weight of a roll of polyester mesh, which can vary depending on the dimensions and density.

|